3D CAD / CAM design

Company Raster offers services of 3D CAD/CAM design for standard or complex architectural buildings and constructions made of timber. We offer our expertise to architects and manufacturers of passive and low energy prefabricated houses and buildings, producers of log houses, producers of trussed rafter constructions and other complex architectural constructions made of timber. We integrate specialized knowledge of various fields to help architects, engineers and manufacturers bridge the gap between an idea and realization. Our services bring standard and non standard architecture to life in the most effective way.

The company's wide experience and knowledge of production methods and material properties enable us to simplify the complexity of architecture, a building’s details and to make projects easy and user friendly. Our software solutions give us the possibility to optimize material consumption and to lower different costs for the producer. Our contributions for clients are 3D models of a project, 3D visualization of buildings and construction details, shop drawings (production drawings), material lists and CNC (CAM) files.

Passive and low energy timber houses and buildings

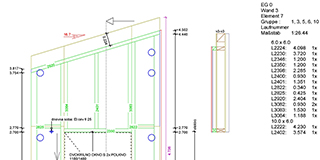

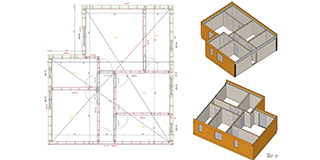

Company Raster designs 3D CAD/CAM models and prepares all necessary production drawings, details, material lists and CNC codes for industrial production of passive and low energy consumption houses with sustainable construction and non construction materials.

Houses can be designed in a timber frame or an X-lam construction system. According to static calculation we use solid timber, I-joist and glulam construction elements. The walls, floor and roof can be designed to be produced in elements (prefabricated). Before creating a 3D model we predefine the building’s elements (walls, floor, roof), connection details, details of windows’ and doors’ openings to suit production process, material requirements, building standards and assembly on site. Our production drawings of walls, floors etc. includes all necessary markings and details from electrical installation, water installation, heat installation, ventilation and other house installation projects. CNC codes can be prepared in BVN, BTL or other CNC format.

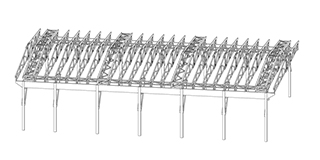

Buildings with trussed rafter constructions (with nail plates)

Company Raster designs 3D CAD/CAM models and prepares all necessary production drawings, details, material lists and CNC codes for buildings with trussed rafter constructions (with nail plates). Trussed rafters are load bearing constructions. They can be used wisely as a wall, roof and floor construction element. Buildings with trussed rafters are cost effective.

Log houses

Company Raster designs 3D CAD/CAM models and prepares all necessary production drawings, details, material lists and CNC codes for industrial production of log houses with rectangle logs. Log wall connections, windows, doors and installations details are constructed according to a log house building’s standards. Our production drawings of walls include all necessary markings and details from electrical installation, water installation and heat installation projects.

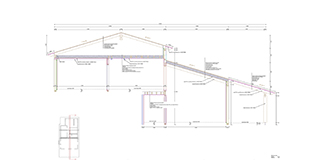

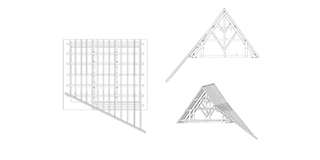

Glulam and solid timber building constructions

Company Raster designs 3D CAD/CAM models and prepares all necessary production drawings, details, material lists and CNC codes for glulam and solid timber building constructions. We design constructions for classic roofs, barns, stables for horses and cattle, production and warehouse buildings. Constructions are designed according to static calculation, building standards and assembly methods. CNC codes can be prepared in BVN, BTL or other CNC format.

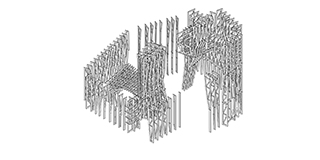

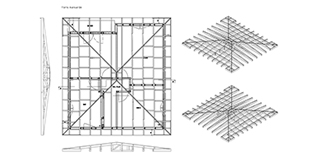

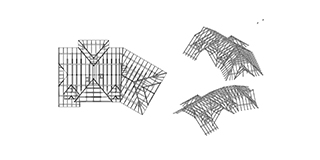

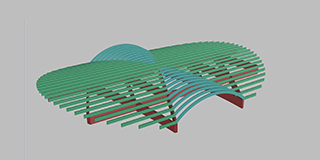

Parametric 3D CAD/CAM design - Complex architecture

We implement customized parametric 3D CAD/CAM models for design and CNC manufacturing purposes of a complex architectural design. With our 3D models we help refine design concepts and define control parameters. A parametric 3D model gives us large possibilities to manipulate with architectural projects. During the optimization process we optimize the complexity of an architectural form to a production and cost effective stage. We use advanced algorithmic optimization tools that match design ideas to the best constructive, structural and functional solutions. We simplify complexity of the details by rationalizing complex designs based on a thorough understanding of the production process. We constantly examine new materials, components and fabrication technologies in order to find simple solutions for complex forms. The geometry and complete fabrication data is automatically generated from a parametric 3D model. Our output is a parametric 3D CAD/CAM model, plan drawings for buildings and production, BTL CNC codes for production process.

View 3D model...